EQM

WE ARE DIFFERENT

As one of the leading production and development companies in the aviation industry, we stand out thanks to our core competencies – engineering, quality and manufacturing (EQM) – and thus give our customers a crucial competitive advantage in a keenly fought market.

Engineering

We develop your competitive advantage through innovative solutions.

Quality

We guarantee the highest quality standards through state-of-the-art processes.

Manufacturing

We produce at the highest precision using the latest manufacturing technologies.

ENGINEERING

Solution-oriented working methods – even taking into account the strict requirements seen in the aviation industry, our team is able to find customer-oriented solutions and implement them according to specific demands. Functionality and quality factors are considered at all times here.

From simple washers through to complicated mechanical assemblies – SACS Aerospace ensures that all projects are implemented in a success-oriented way thanks to its accumulat-ed expertise and many years of experience. In addition to increasing development in the environmental field (e.g. REACH), the use of 3D printing technologies is also growing constantly. Faster verification of development steps is possible thanks to prototype construction using 3D printers, testing capabilities with climate chambers, Kuka-robot for endurance tests, salt spray chamber and machines for testing tensile and compressive strength.

20

number of new projects

20.000

number of development hours per year

30

number of solid work stations

Engineering Services :

What we offer our customers:

QUALITY

Quality at the highest level – SACS Aerospace stands for durable, high-quality system assemblies and product assemblies made in Germany.

We carry out a systematic feasibility study as early as the tendering phase while taking into account all applicable quality requirements. By using innovative quality management tools, we are able to identify potential sources of errors in good time and avoid them. By connect-ing together product and process FMEA, potential functionality issues can be ruled out – including in series production. 100% quality: The successful implementation of a zero-defect strategy is possible thanks to fast quality control loops in production, technical planning and reliable quality management in all manufacturing areas.

2.800

number of inspection equipment

50

number of qualifications per year

1 Mio.

number of test cycles per year

What we offer our customers:

In-house innovation and technology center with qualification support – right up to the start of series production via QTP / QTR in cooperation with our customers:

Use of the latest measuring techniques and applications throughout the entire manufacturing area:

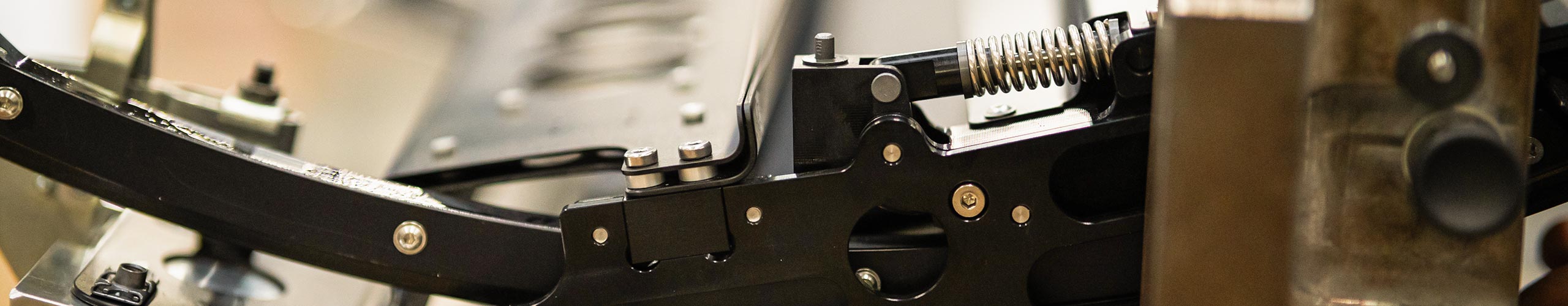

MANUFACTURING

High-precision manufacturing – SACS Aerospace uses state-of-the-art five-axis milling ma-chines, three-axis milling machines and CNC lathes. Integrated measuring stations and per-manent, IT-logged measurements with defined test instructions are standard practice. Our MES system means we can intervene in the manufacturing process flexibly and respond to customer requests. All production data is completely transparent and can be viewed and analyzed at any time. Exact predictions and planning are then possible.

Materials:

Technologies:

Fast jobs:

Faster delivery times and AOG deliveries are possible as all production steps are combined under a single roof. Dedicated resources and production sequences are assigned to “Fast Shop” orders.

Toolmaking (development and production):

Process qualifications:

Joining Techniques:

Installation, Manufacture, Fabrication:

Paints, Coatings, Filler, Sealant:

Bonding:

Non Destructive Testing: